Hastelloy X

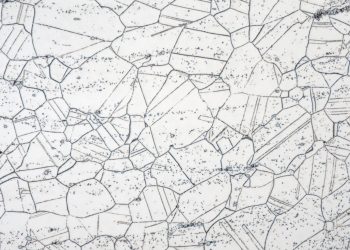

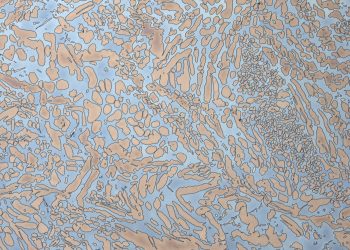

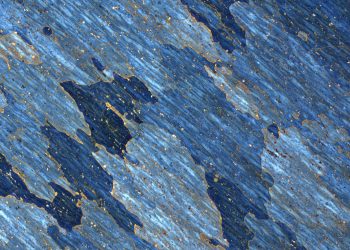

Nickel-based superalloys are often used in demanding applications and environments. Two of the most common applications of nickel-based superalloys are petrochemical parts subject to corrosion and gas turbine components which are subjected to heat and combustion by-products. One...