The other day, the bolts that held on my license plate had

gotten rather rusty and I wanted to prevent the rust from staining the license plate

(one of my pet peeves is a dirty car). Therefore, I took a trip to Lowes and

grabbed a few stainless screws and bolts to replace the hardware so hopefully the

hardware remains aesthetically pleasing.

However, one of my curiosities was what type of stainless

steel is used in these cheap fasteners since each piece of hardware was relatively

inexpensive and the type of alloy was not specified. Also, looking at the

threads they appeared rolled so would this require subsequent heat treating to either

temper the martensite that may form from the rolling or re-solution the alloy

to achieve a homogonous microstructure? Consequently, I grabbed an extra

stainless bolt and an extra carbon steel bolt to see what I would find in a

cross section.

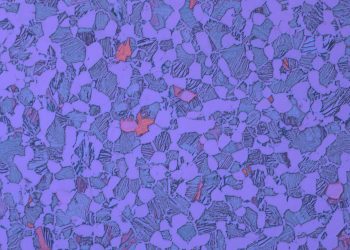

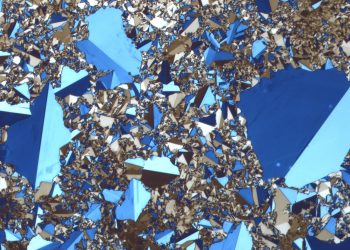

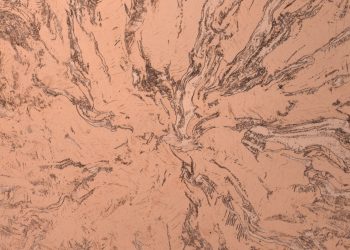

The below photomicrographs are of a sample of first the stainless-steel

bolt then a carbon steel bolt at various magnifications. The samples were

mounted longitudinally, ground, and polished to a sub-micron finish and etched

using Marbles Reagent (stainless) or Nital (steel). The stainless-steel

fastener shows a microstructure that consists of cold worked austinite and martensite

in the area immediately below the surface of the rolled thread. The steel

fastener shows a tempered martensite microstructure. However, on both samples

there are cracks that seem to be the result of the tread rolling process.

Marbles Reagent:

10 grams Copper Sulfate, 50mL Hydrochloric Acid, 50 mL Water

Nital (2%)

98 mL Ethanol, 2 mL Nitric Acid