Aluminum is a material that is often used for its strength to

weight ratio, good machinability, corrosion resistance, and cost. Aluminum 6061

is the most commonly used aluminum alloy. It contains magnesium and silicon as

its primary alloying elements and is precipitation hardenable.

While 6061 is precipitation hardenable, grain

size does impact the strength of the alloy due to grain boundary strengthening.

Typically, fine equiaxed

grains are desired to maximize strength and ductility.

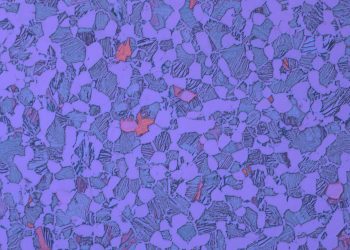

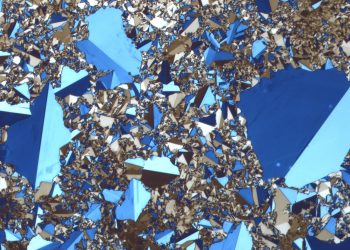

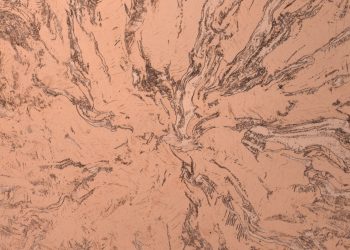

For many

aluminum alloys, it is very difficult to reveal the grain boundaries of the

alloy. The below photomicrographs show a 6061 alloy with elongated grains. The

grain boundaries were revealed using a two-step etch. First, Graff-Sargent

reagent was used. Then, Weck’s TInt etch was used on the sample. This two-step

etch allowed crisp grain boundaries to be resolved as well as many of the

intermetallic precipitates within the grains and along the grain

boundaries.

Graff-Sargent

Reagent:

84 mL water,

15.5 mL nitric acid, 0.5 mL hydrofluoric acid, 3 grams chromium trioxide

Weck’s Tint Etch:

100 mL water, 4 grams potassium permanganate,

1 gram sodium hydroxide