Nickel-based superalloys are often used in demanding

applications and environments. Two of the most common applications of nickel-based

superalloys are petrochemical parts subject to corrosion and gas turbine components

which are subjected to heat and combustion by-products.

One commonly used nickel-based superalloy is Hastelloy X. It

is a nickel-chromium-iron-molybdenum alloy that offers high temperature strength,

hot corrosion resistance, oxidation resistance, and is readily formable/weldable.

It is a precipitation strengthened nickel-base superalloy that can be aged to

increase the strength of the alloy. It can also be solution treated for

enhanced formability and weldability and then re-solutioned and aged for optimal

mechanical properties.

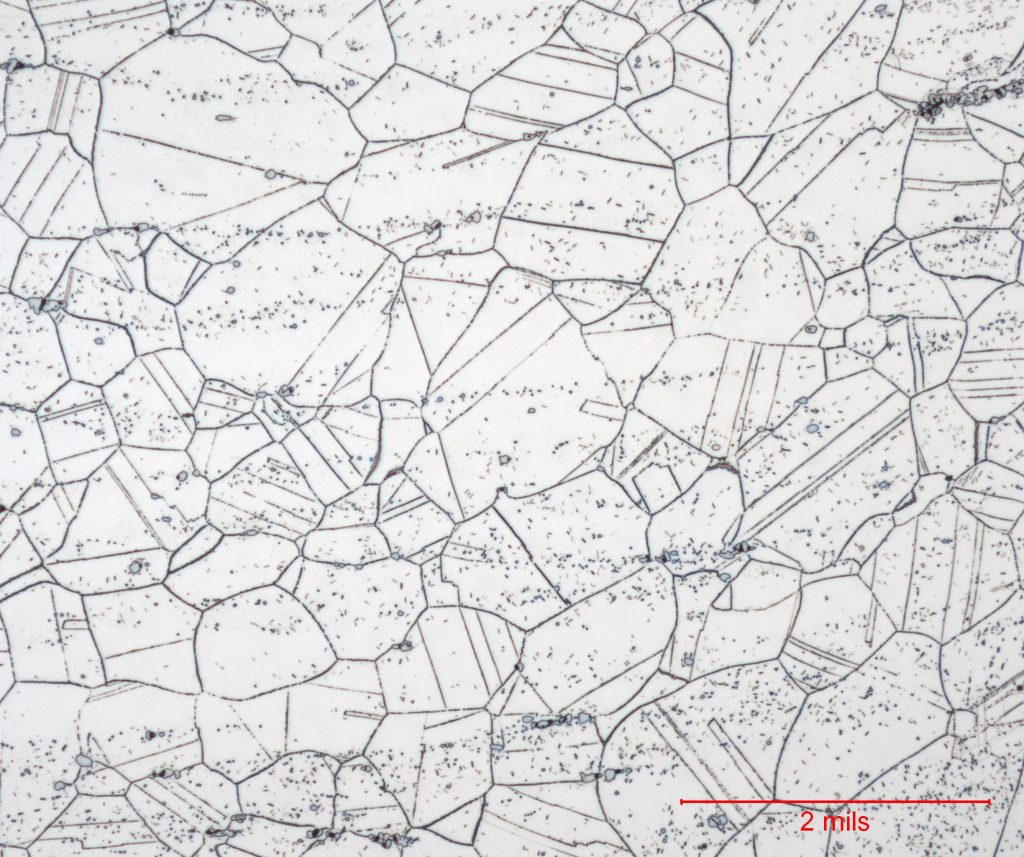

The below photomicrograph of Hastelloy X is taken at a

magnification of 500X. The sample was prepared from a piece of Hastelloy X

round stock which was ground and polished to a sub-micron final polish. The sample

was etched using Waterless Kalling’s Reagent. The sample microstructure consists

of equiaxed twinned grains with intragranular large MC carbides and finely

dispersed small carbides.

Waterless Kalling’s:

Cupric Chloride 12 grams, Hydrochloric Acid 20 mL, Ethanol

225 mL