One of the first true superalloys was A286 super stainless

steel which was developed in the 1930s. The superalloys of this era consisted

of mostly iron or nickel base alloys with additions of chromium for oxidation

resistance. However, with time applications such as rockets and jet engines

greatly spurred superalloy development.

A286 is a very capable material and still in use today. It

is a precipitation hardened stainless steel which is used in applications that

require superior corrosion resistance and high strength. While alloys such as

316 offer good corrosion resistance, their strength is low due to their lack of

hardenability. The hardenability is achieved in A286 by the presence of titanium

and aluminum which act to form precipitates during an ageing heat treatment

known as gamma prime.

Additionally, since the primary constituents of the alloy

are iron, nickel, and chromium the alloy is readily machined, formed, and

welded when compared to newer and more sophisticated nickel-base superalloys.

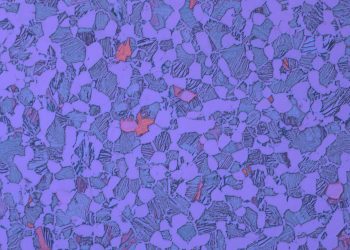

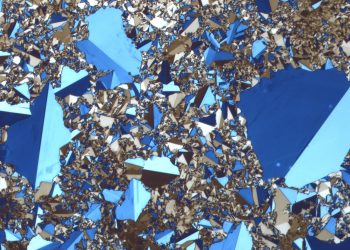

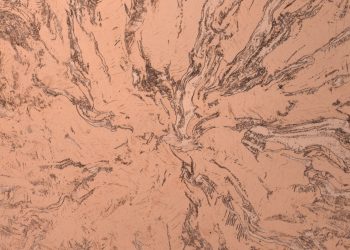

The below photomicrographs are taken at magnifications of

100X, 200X, and 500X. The sample was cut from a piece of A286 bar stock which

was ground and polished to a sub-micron final polish. The sample was etched

using a modified mixed acids etchant. The sample microstructure consists of a

fine equiaxed twinned grain structure (solid solution matrix (austenite)) and

occasional MC carbides.

Modified Mixed Acids:

15 mL Hydrochloric Acid, 10 mL Acetic Acid, 10 mL Nitric

Acid