Update: Titanium alloys are typically etched using a grain boundary etchant such Kroll’s or 2% HF. In the case of alpha case evaluations, a tint etch such as ammonium fluoride is used to provide greater contrast between the alpha and beta phases and it can be used to show grain orientation in commercially pure titanium. However, one curiosity I had was to attempt an anodizing etch after a grain boundary etch to see if compositional differences could be identified.

I took sample from my previous alpha beta titanium blog post and subsequently ground until it was plane and fine ground the sample to 400 grit. Then, a Struers MD Allegro Pad using 9 micron diamond suspension was used to plane the sample for about 5 minutes using 30N of force per sample. Afterwards, a Struers MD Largo Pad using 9 micron diamond suspension was used to polish the sample for about 10 minutes (30N per sample). Afterwards, a Struers OP-Chem Pad was used with a colloidal silica suspension and chemical addition to mechanically and chemically polish the surface for 3.5 minutes (30N per sample). Then the sample was etched using Kroll’s Reagent.

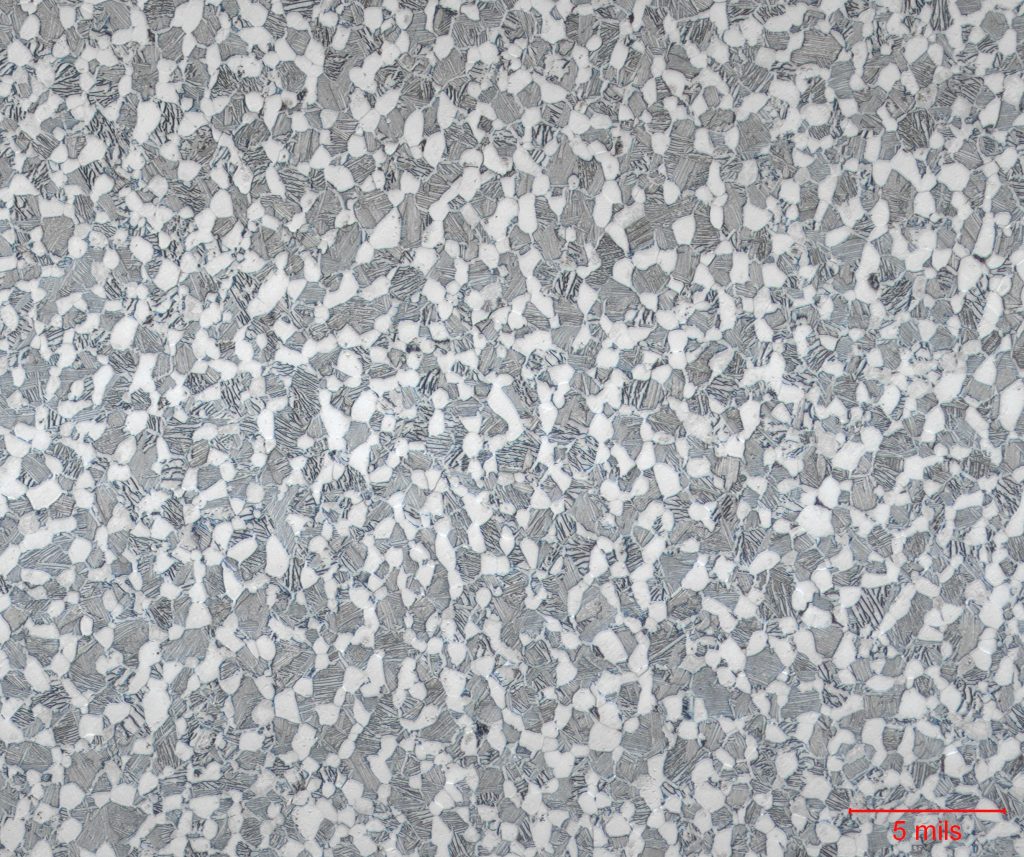

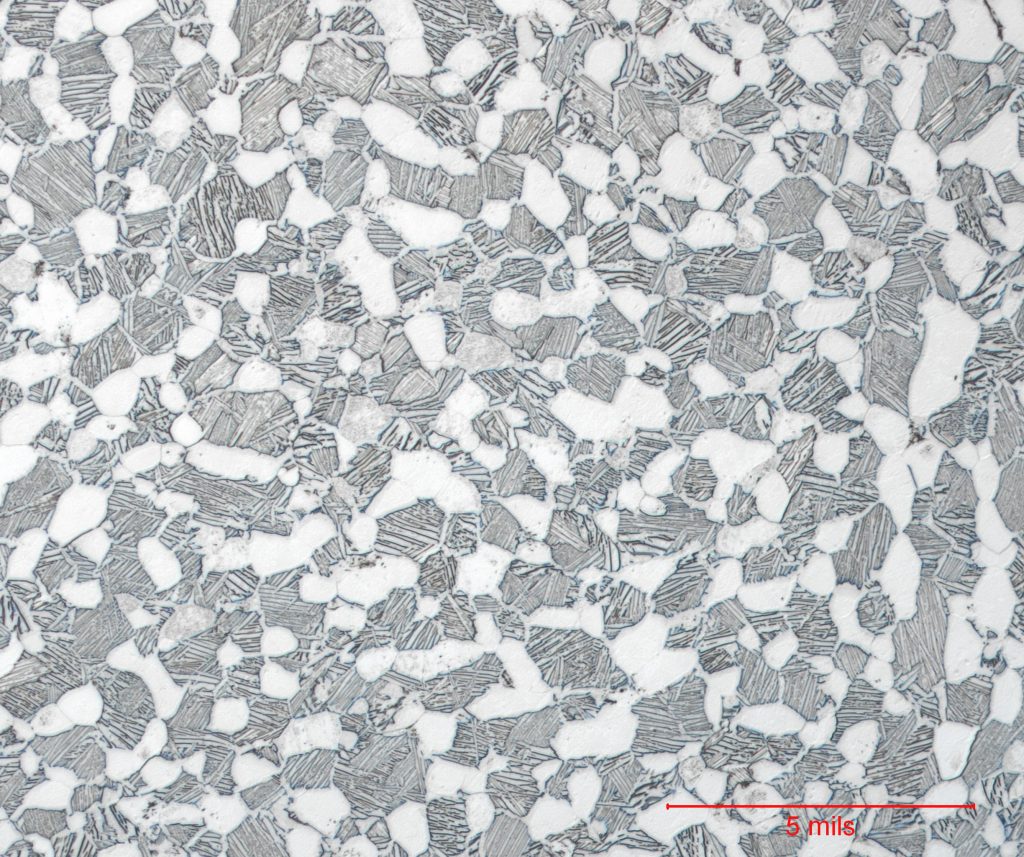

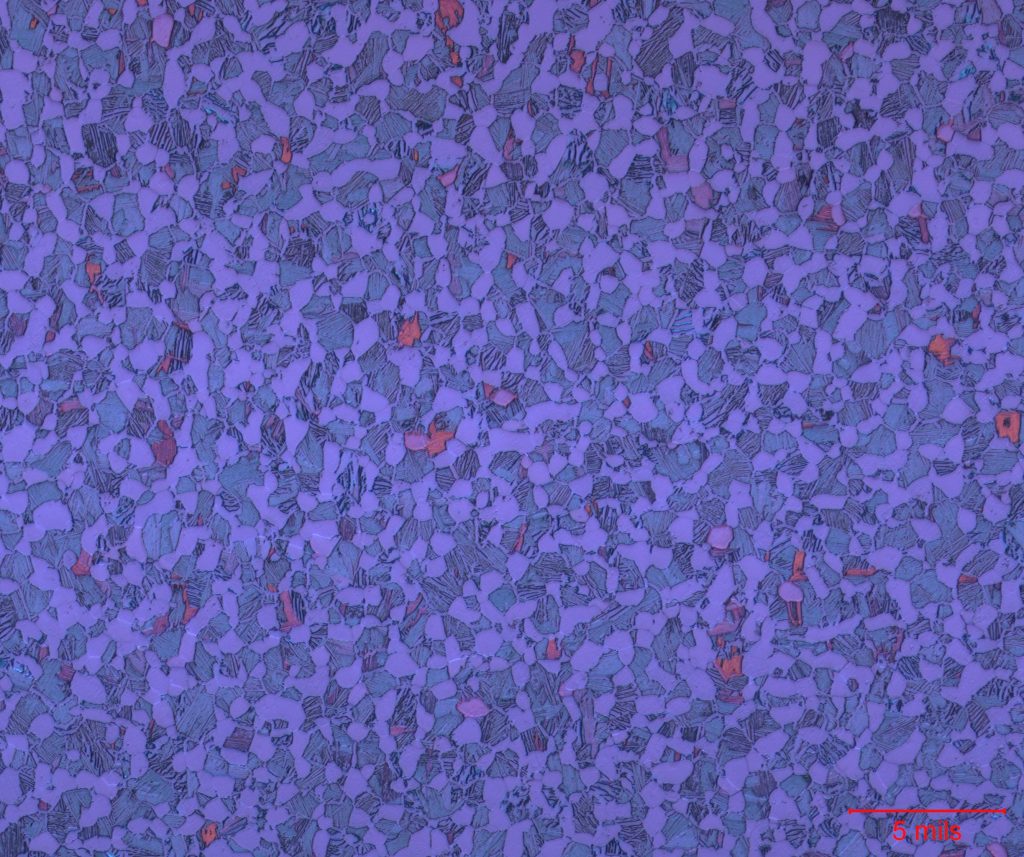

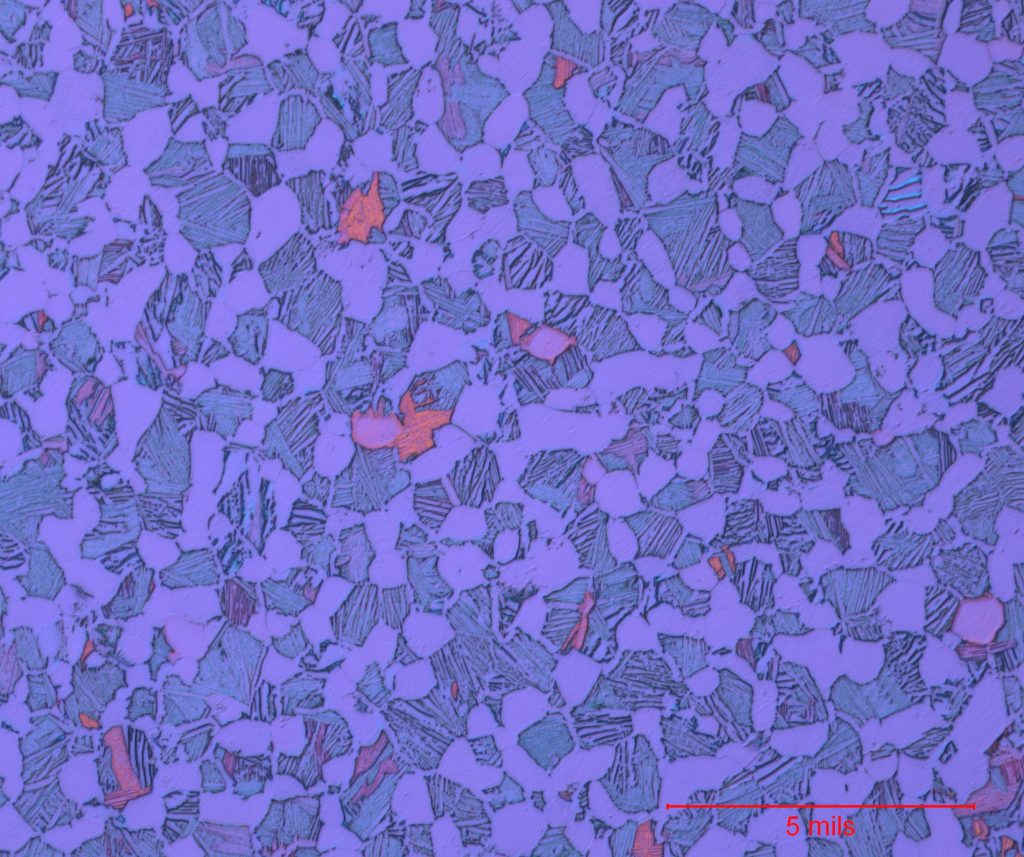

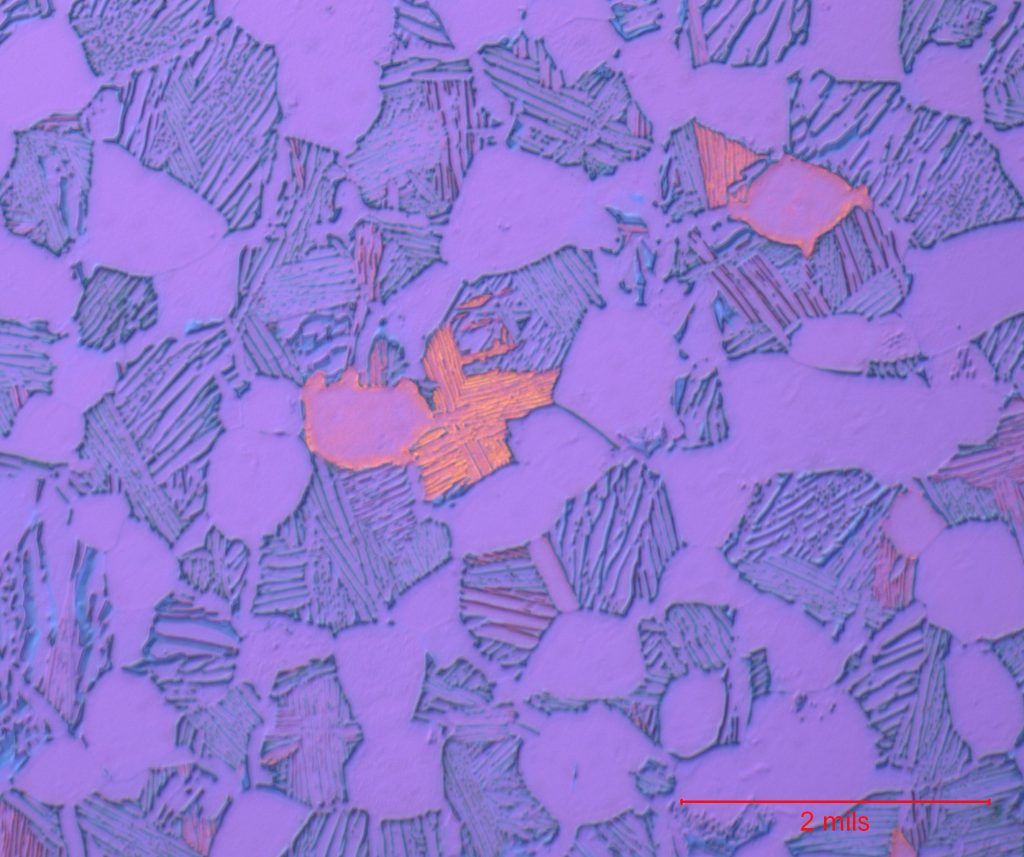

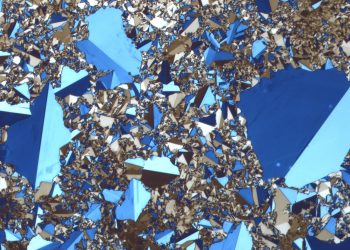

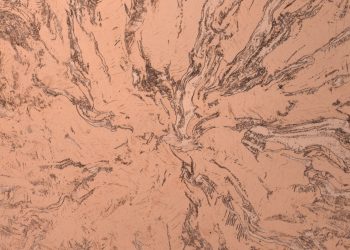

The below photomicrographs show the sample microstructure at magnifications of 100X, 200X, and 500X. The sample microstructure consists of equiaxed primary alpha in a matrix of transformed beta containing fine acicular alpha. Afterwards, the sample was anodized using the anodizing etch listed below at 115V for 5 seconds. The second set of photomicrographs show the results of the anodizing process which appears to perhaps show compositional differences in the microstructure which would have to be verified by EDS.

Chemical Polish:

150 mL Colloidal Silica, 15 mL Ammonium Hydroxide, 5 mL Hydrogen Peroxide (30% concentration)

Kroll’s Reagent:

3 mL Hydrofluoric Acid, 6 mL Nitric Acid, 91 mL Water

Anodizing Etch:

60 mL Ethanol, 35 mL Water, 20 mL Glycerin, 10 mL Lactic Acid, 5 mL Phosphoric Acid, 2 grams Citric Acid

Thanks for the post

_________________

Вася Роговтың жойқын күші казинолықда ойнайды

Hi! Just wondering- what template did you use for your website? I want to use it on my blog at https://similar.my.id