There are countless nickel-based superalloys with the most

famous of them often being Inconel 718 which is often used in gas turbine

applications. In fact, Inconel 718 is so commonly used in gas turbines that it

often can account for 30% of the weight of a typical jet engine. 718 has exceptional

mechanical properties for use in high temperature environments (approximately up

to 1200 degrees Fahrenheit) while maintaining acceptable machinability, weldability,

and formability.

Inconel 718 is a precipitation hardenable nickel-based

superalloy which is primarily comprised of nickel, and chromium. It also has

alloying additions of iron, niobium, molybdenum, aluminum, and titanium. The

alloy is hardened by the precipitation of the secondary phases (gamma prime and

gamma prime prime) during aging treatment which is done following a solution

anneal. During the aging treatment, which is carried out at approximately 1400 degrees

Fahrenheit for 10 hours, the gamma prime and gamma prime prime phases precipitate

out of solution and strengthen the alloy.

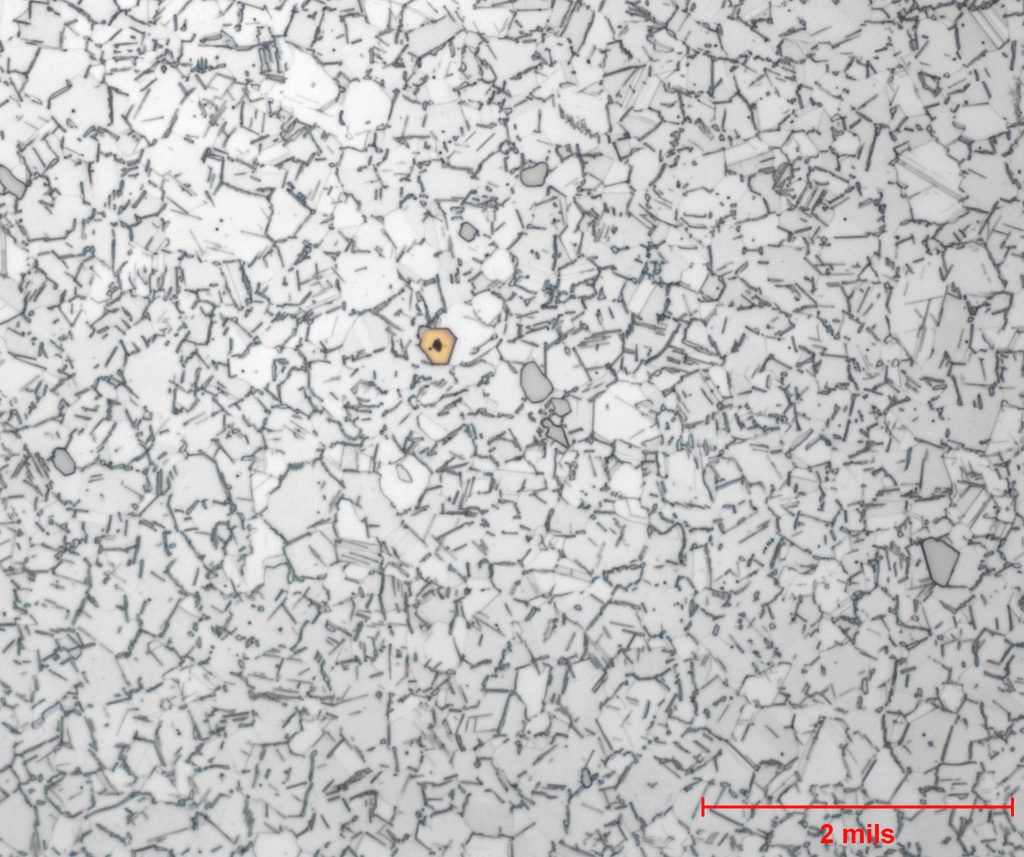

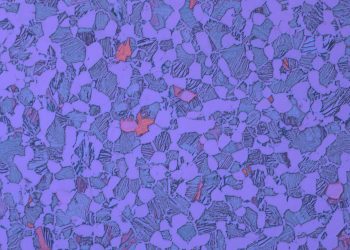

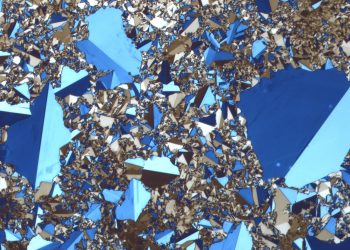

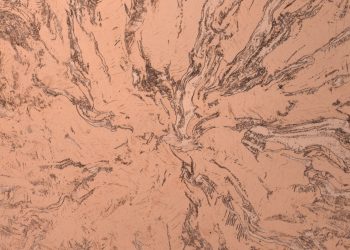

The below photomicrographs are taken at magnifications of

100X, 200X, 500X, and 1000X. The sample was cut from a piece of 718 bar stock which

was ground and polished to a sub-micron final polish. The sample was etched

using Waterless Kalling’s Reagent. The sample microstructure consists of Ni3Nb in

a gamma matrix with a fine equiaxed twinned grain structure and occasional MC

carbides.

Waterless Kalling’s:

Cupric Chloride 12 grams, Hydrochloric Acid 20 mL, Ethanol

225 mL